Boost Efficiency: Necessary Tips for Keeping Undercarriage Parts Performance

Wiki Article

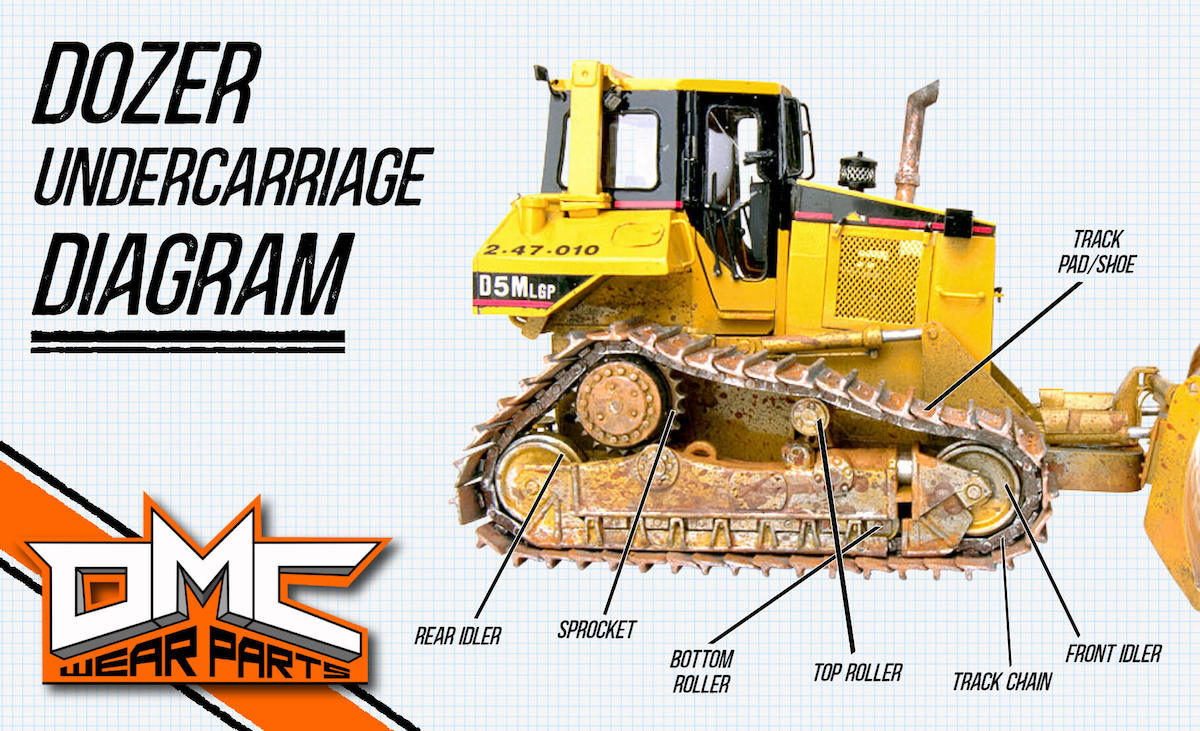

Optimize Performance With Resilient Undercarriage Parts

In the realm of hefty equipment and equipment, the function of undercarriage components is vital in guaranteeing optimal performance and durability. The effectiveness and effectiveness of these components can substantially affect the overall operation of machinery, making the selection of resilient undercarriage components a critical choice for drivers and supervisors alike. By checking out the intricate partnership in between resilience and performance in undercarriage parts, a deeper understanding of the subject arises, clarifying the critical variables that drive functional success. As we browse with the intricacies of undercarriage maintenance, longevity, and part selection, an extensive exploration awaits to unveil the essential methods for achieving peak efficiency in sturdy applications.Benefits of Making Use Of Resilient Undercarriage Parts

Making use of durable undercarriage parts not just improves the long life of heavy machinery however likewise reduces maintenance prices considerably. By purchasing premium undercarriage parts, such as tracks, idlers, rollers, and gears, tools operators can experience boosted uptime and boosted general efficiency.

Furthermore, the durability of hefty equipment is directly linked to the top quality of its undercarriage parts. Sturdy components can hold up against the rigors of requiring applications, making certain that the devices remains functional for extended durations. Therefore, drivers can stay clear of expensive downtime and maintenance expenses, ultimately taking full advantage of the return on financial investment for their equipment.

Elements Influencing Undercarriage Durability

The toughness of undercarriage parts in hefty machinery is affected by different vital elements that straight influence efficiency and longevity. Among the vital aspects influencing undercarriage sturdiness is the quality of products made use of in production. Top notch products, such as hard steel, are vital for withstanding the extreme problems and heavy loads that undercarriage components go through. Correct upkeep methods likewise play a critical function in identifying the life expectancy of undercarriage parts. Normal examinations, lubrication, and timely replacement of damaged components can dramatically prolong the resilience of the undercarriage.Furthermore, ecological factors can have a significant influence on the long life of undercarriage components. Direct exposure to rough materials, severe temperature levels, and harsh working problems can speed up wear and tear on undercarriage parts. Picking undercarriage parts that are particularly developed to withstand these ecological difficulties is important for making sure resilience.

Additionally, the design and design of undercarriage components have a direct influence on their durability. Parts that are developed to distribute tons uniformly, minimize friction, and reduce anxiety focus are more probable to have a much longer lifespan - undercarriage parts. By considering these vital factors, tools operators can maximize the sturdiness and efficiency of their undercarriage elements

Maintenance Tips for Lengthening Undercarriage Life

Implementing normal maintenance routines is crucial for prolonging the life-span of undercarriage components in hefty machinery. Additionally, ensure that the undercarriage is properly oiled according to manufacturer guidelines to decrease friction and stop early wear.Another crucial maintenance idea is to maintain the undercarriage tidy from dirt, rocks, and debris. Build-up in the undercarriage can speed up wear and deterioration, causing expensive repair work. Cleaning the undercarriage after procedure in rough conditions is recommended to avoid these concerns.

Lastly, monitoring and recording upkeep activities can assist in creating a proactive upkeep schedule. Keeping detailed records of repair services, replacements, and evaluations can offer valuable insights right into the undercarriage's condition and efficiency gradually, assisting in anticipating and preventing possible failures. By following these maintenance tips diligently, visit the website operators can considerably increase the longevity and performance of undercarriage components in hefty machinery.

Choosing the Right Undercarriage Components

Picking proper undercarriage elements is vital for making best use of the effectiveness and durability of heavy machinery. When it comes to picking the right undercarriage parts, there look these up are numerous factors to think about.Deciding for reliable brand names recognized for creating sturdy and high-performance undercarriage parts can considerably affect the overall performance and durability of the machinery. By meticulously selecting the ideal undercarriage elements, equipment proprietors can improve efficiency, lower downtime, and expand the lifespan of their heavy equipment.

Study: Improved Performance With Durable Components

Integrating long lasting undercarriage parts has actually demonstrated considerable enhancements in equipment efficiency. One situation study involved a building company that updated its excavator's undercarriage elements to extra long lasting options. The firm observed a noteworthy reduction in downtime as a result of undercarriage upkeep, leading to boosted efficiency and expense financial savings. The long lasting parts stood up to extreme working conditions, lowering damage dramatically.In one more circumstances, a mining procedure changed the undercarriage parts of its bulldozer with high-quality, durable alternatives. This button brought about an exceptional enhancement in the excavator's maneuverability and overall efficiency. The machine could navigate tough surfaces more efficiently, bring about enhanced operational efficiency and lowered gas intake.

Additionally, a logging firm bought resilient undercarriage components for its forestry equipment. The upgraded elements showed long term life expectancy and raised resistance to abrasion from harsh surface. The business experienced decreased upkeep expenses and improved devices uptime, ultimately boosting its bottom line. These case studies underscore the tangible benefits of utilizing long lasting undercarriage parts in enhancing machinery performance and durability.

Final Thought

In final thought, making use of resilient undercarriage components can dramatically enhance performance and durability of hefty equipment. Instance researches have actually shown that investing in durable undercarriage parts can lead to enhanced overall you can look here performance and efficiency in various sectors.The efficiency and efficiency of these parts can dramatically influence the overall operation of equipment, making the option of sturdy undercarriage parts a crucial decision for drivers and managers alike.Integrating sturdy undercarriage components has demonstrated considerable enhancements in machinery efficiency. These case studies highlight the concrete advantages of using sturdy undercarriage parts in optimizing machinery efficiency and longevity.

In verdict, utilizing resilient undercarriage components can dramatically boost performance and long life of heavy machinery (undercarriage parts). Instance studies have revealed that spending in sturdy undercarriage components can lead to improved general efficiency and efficiency in various sectors

Report this wiki page